When a CCD device reads out a digital signal, the device itself generates a level of noise which is present in the subsequent image produced by the device. Bias noise is a background level of noise which will be present in all images. It arises primarily due to noise in the electrical readout equipment (Johnson-Nyquist noise).

Structure

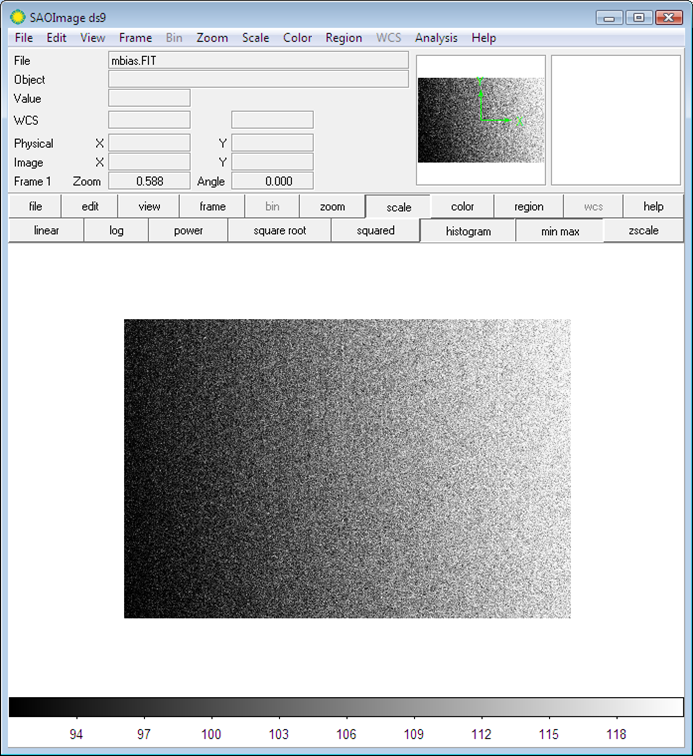

The readout process involves charge transfer betwen neighbouring pixels. This can cause pixels near the readout pixel of the device to retain residual charge and appear 'hotter' than their neighbours. The can result is a net gradient across the CCD bias frame, as can be observed in Fig. 1 and explained in Fig. 2.

Operating Temperature

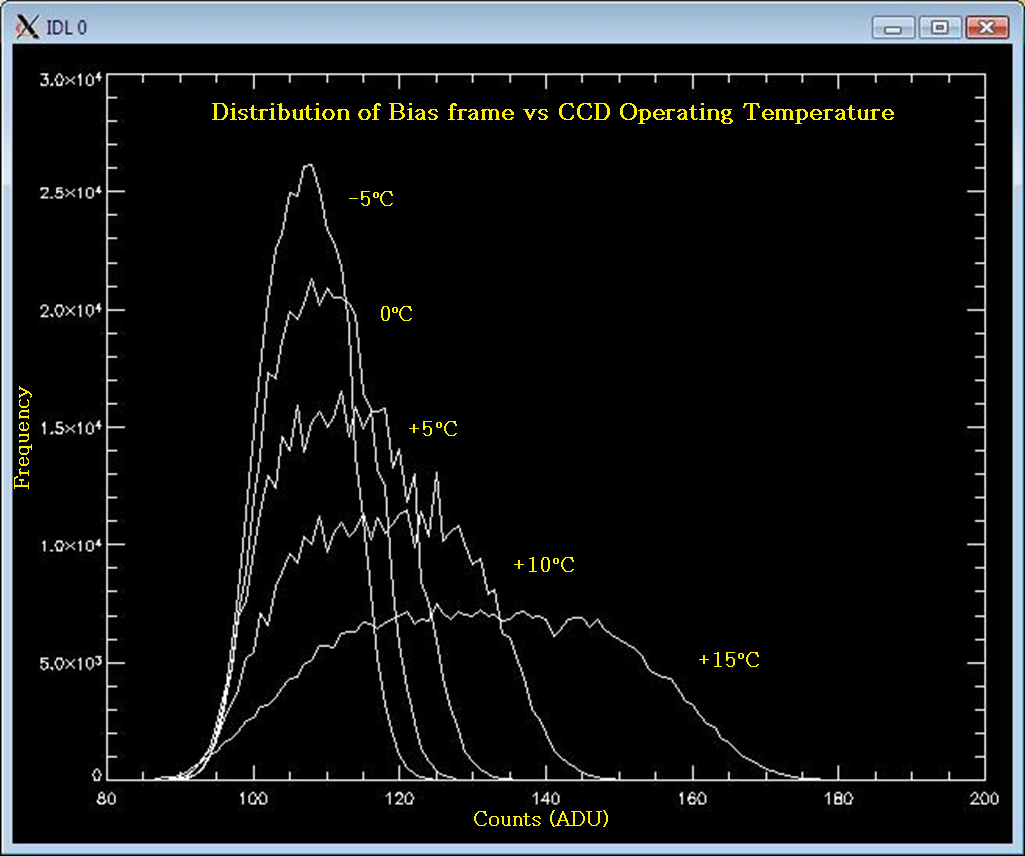

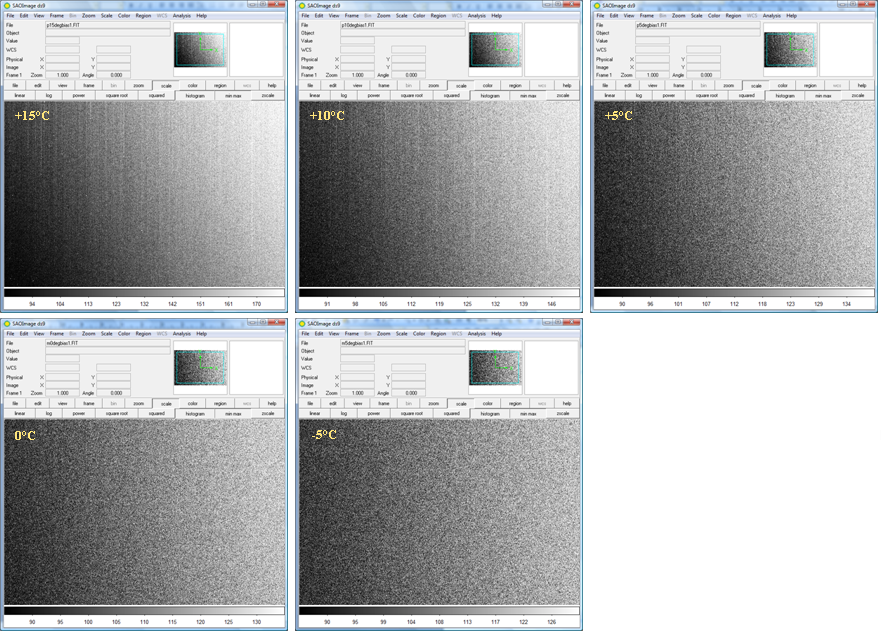

As Johnson-Nyquist noise is dependant on temperature, the bias signal generated from a device will vary with its operating temperature. The greater the operating temperature of a device, the greater the effect Johnson-Nyquist noise has on the readout process. This is most elequenty demonstrated when comparing the resulting bias structure whilst varying the operating temperature.

As Figs. 3a & 3b demonstrate, as the operating temperature of a CCD device increases, the severity of the bias structure increases which in turn increases the mean and distribution of the CCD array pixel values. As excessive bias structure is an unwanted source of noise in astornomical data, it is preferable to reduce the severity of the structure where possible. This is a fundamental argument for choosing a low operating temperature of a CCD device (as well as reducing the rate of electron production, thereby preventing pixels reaching Full Well Capacity with minimal signal counts).

An operating temperature of -5°C was used for the Coldrick SBIG ST-7E CCD device during the 2010-11 BSc Project.

Data Reduction

Providing a constant operating temperature is maintained, the bias frame produces a similar structure and distribution. The bias can therefore can be regarded as a consistent source of noise and subsequently subtracted from all raw images produced. This process is called known as bias subtraction and is typically the first step of the data reduction process.

In order to subtract a bias frame from a raw image produced, a series of bias frames must be taken at the same operating temperature and background light conditions (in a dark room for calibration purposes). Once these frames have been obtained, IDL can be used to generate a master bias frame by taking a median frame of the subsequent frames. Fig. 1 depicts the master bias frame used in the 2010-11 Final Year Project.

Once a master bias frame has been generated for a particular device at a particular operating temperature, it can be subtracted from any raw images subsequently taken by the device. Providing the operation temperature of the device remains constant and the device is not altered or damaged, no further bias calibration needs to be performed.

Raw images which have undergone bias subtraction as known as bias subtracted images.